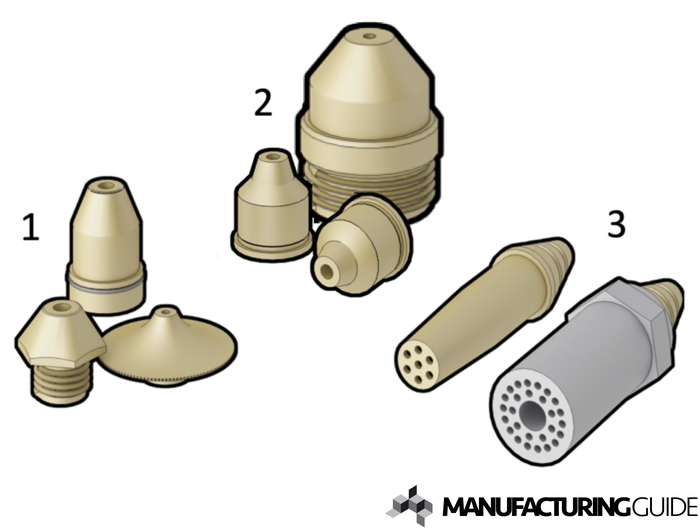

Spray Nozzles

We are a leading Manufacturer of spray nozzles, ss spray nozzle, fog nozzle, hollow cone nozzle, flat fan nozzle and full cone nozzle from Hyderabad, India.

Manufactures custom designed Nozzles as per requirement

A spray nozzle is a precision device that facilitates dispersion of liquid into a spray. Nozzles are used for three purposes: to distribute a liquid over an area, to increase liquid surface area, and create impact force on a solid surface. A wide variety of spray nozzle applications use a number of spray characteristics to describe the spray.

Electrical Power Generation

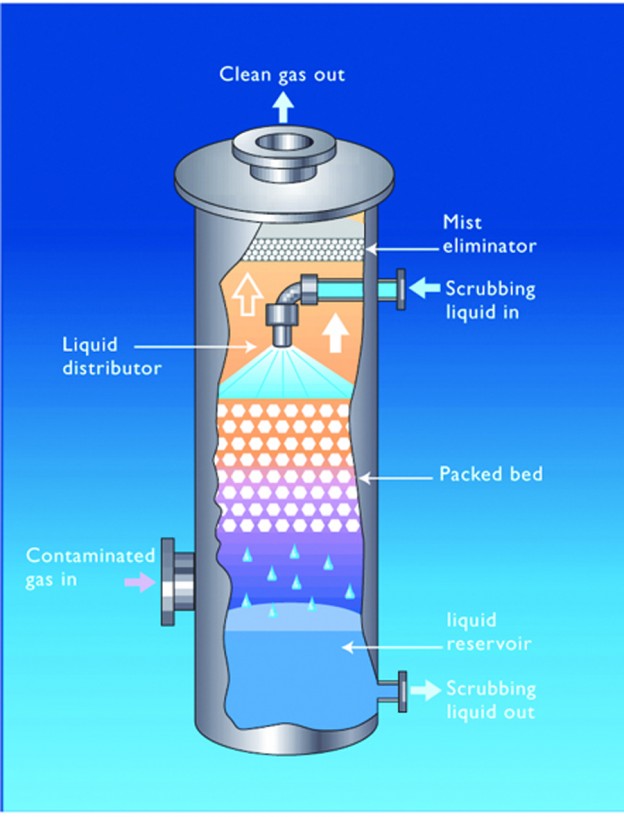

Limestone slurry is sprayed with single fluid spray nozzles to control acid gas emissions especially sulfur dioxide (SO2) emissions from coal-fired power plants with liquid scrubbers. Calcium hydroxide (lime) is atomized into a spray dryer absorber to remove acid gases (SO2 and HCl) from coal-fired power plants. Water is sprayed to remove particulate solids using a spray tower or a cyclonic spray scrubber Cooling towers use spray nozzles to distribute water.

Food and beverage

- Sprays are used to wash fruits and vegetables.

- Spray drying is used to produce hundreds of food products, including instant coffee, powdered soups, and flavor concentrates.

- Coating of food products with flavorings and surface additives.

- Cleaning and sanitizing storage tanks, and process equipment single fluid nozzles are used to rinse and wash away materials. These specialized tank-cleaning nozzles often have a fluid powered rotary motion to increase cleaning effectiveness.

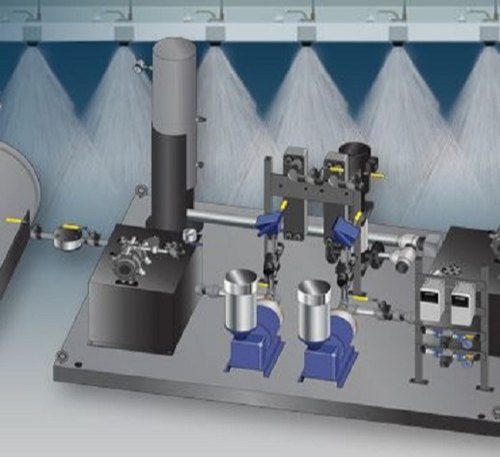

Manufacturing

Sprays are used extensively in manufacturing. Some typical applications are applying adhesive, lubricating bearings, and cooling tools in machining operations.

- Cleaning components with sprays of hot water and detergent sprays for degreasing, electric motor rebuilding, diesel engine rebuilding, plant maintenance, steel mill bearings, railroad bearings and engine rebuilding.

- High pressure sprays are used to de-burr machined parts.

- Spray painting is broadly used in many manufacturing processes; for example, for automobiles, appliances, office furniture.

Paper Making

- High pressure debarking

- Coating paper

- Cleaning rolls

- Trimming paper

Fire Protection

- Spraying water from fixed sprinklers

- High pressure water misting systems for expensive and delicate equipment, for example, marine engine rooms.

- Deluge systems for protecting assets or keeping potentially explosive materials cool in the event of fire (e.g. gas canisters)

- Water tunnel systems designed to ensure a safe “cool” corridor to allow people to escape in the event of fire.

Mining

· Water sprays are critical to reducing coal dust during mining

· Water is sprayed to control dust emission produced during grinding; spray nozzles are also used for washing gravel in screening plants.

Lime and Cement

· Suppressing dust from raw materials.

· Feeding fuel to high temperature calcining rotary kilns.

· Cooling and conditioning gas.

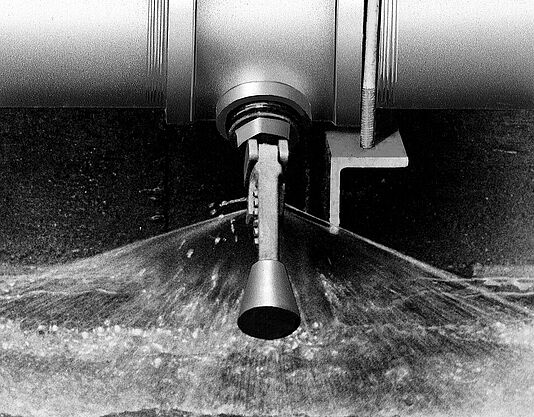

Steel Industry

- High pressure water is used to remove scale (iron oxide) from red hot steel during the process of rolling into sheet or strip forms.

- Sprays are used in the continuous casing process and quenching of hot gases.

- Quenching coke from coke-ovens

- Cooling metal extrusions

- Pickling solutions and rinsing pickling solutions

Chemical, Petrochemical and Pharmaceutical

- Spraying reagents to enhance dispersion and to increase liquid-gas mass transfer. Many systems are used, including spray towers.

- Spray drying fluid cracking catalyst for oil refining

- Washing and rinsing solids in filters and centrifuges

- Applying coating to many pharmaceutical tablets

Waste water Treatment

- Single fluid nozzles are used to break foam in activated sludge wastewater aeration basins and to apply antifoams.

- Water is spray mixed with material being composted.

Agriculture Applications

- Spray application of herbicides, insecticides, and pesticides is essential to distribute these materials over the intended target surface. Pre-emergent herbicides are sprayed onto soil, but many materials are applied to the plant leaf surface.

- Agricultural sprays include the spraying of cropland, forest, turf grass, and orchards. The sprayer may be a hand nozzle, on a ground vehicle, or on an aircraft. Herbicides, insecticides and pesticides are spray applied to soil or plant foliage to distribute and disperse these materials.

- The control of spray characteristics is critical to provide the coverage of foliage and to minimize off target drifting of the spray to adjacent areas. (pesticide drift). Spray drift is managed by applying only in appropriate wind conditions and humidity, and by controlling drop size and drop size distribution.

- Minimizing the height of the spray boom above the crop reduces drift. The spray nozzle type and size and the operating pressure provide the correct application rate of the material and control the amount of driftable fines. Spays, single fluid nozzles, are also used to cool animals.

Consumer Products

Atomizers are used with pump-operated sprays of household cleaning products. The function of these nozzles is to distribute the product over an area.

- Water and detergent sprays for the car washing

Our other Products

we are one of the prominent Manufacturer, Exporter and Trader of Dust Suppression And Extraction System, Pollution Control Equipment, Flow Meters, Booster Pump, Gas Cooling Systems and Scrubber, Water Sprinkler Systems etc. Owing to our stringent focus on developing high-end manufacturing technology for production we have made us a forerunner enterprise in this domain. These products are widely appreciated in the market for their outstanding performance, high accuracy, robustness and long functional life aspects due to their modern age fabrication techniques. Moreover, we have attained wide customer satisfaction through our ethical business policies.

Keeping track of latest industrial developments, we have developed our infrastructure system which encompasses ultra modern manufacturing, quality inspecting and warehousing unit. We put an efficient use of manufacturing and quality unit for making the qualitative assortment of products as per latest industrial norms. Furthermore, with the incorporation of adroit personnel, we have gathered vast clientele base to serve with cement, power, chemical, mining, paper, steel industries as prestigious clients.

Rajendra prasad

Manging Director, Integ Group

enquiry