Dust Suppression Systems

Plain Water Dust Suppression System:

This type of dust suppression system in the coal handling plant is a wet dust suppression system. Wetting Agents are chemicals, if required, that are added to water to improve the rate at which spray droplets wet dust particles.

This system consists of three main parts.Water Pump, Water Tank, etc. Spray headers with pipe lines & pumping system .Control units with electrical systems . Spray header with pipe lines pumping system includes solution pumps, isolating valves, spray nozzles, and pipe lines. The solution pumps are used to supply pressurized water to spray headers. The required quantities of nozzles are used to spray water.

CONTROL UNITS WITH ELECTRICAL SYSTEMS consists of sensing units, control panels. Coal flow is sense by sensor. The control panels are consisting of various relays and transformer.

Operation:Auto control or manual control governs the system. It has to be insured that main tank is filled with water. The water is pumped by feed water pump from main tank to feed water tank. the system in recalculation. The sensing system for controlling spray at proper header ensures spraying solution if conveyor is running with coal. And will not allow spraying solution if conveyors are running empty, the solenoid valve headers are energized if conveyor is running with coal. If all or some of the solenoid valves are not energized the system will realize pressure through pressure relief valve, which protects the system. A solenoid valve is provided with bypass line, which operates when none of the spray header solenoid valves are operative.

Dry Fog Dust Suppression System:

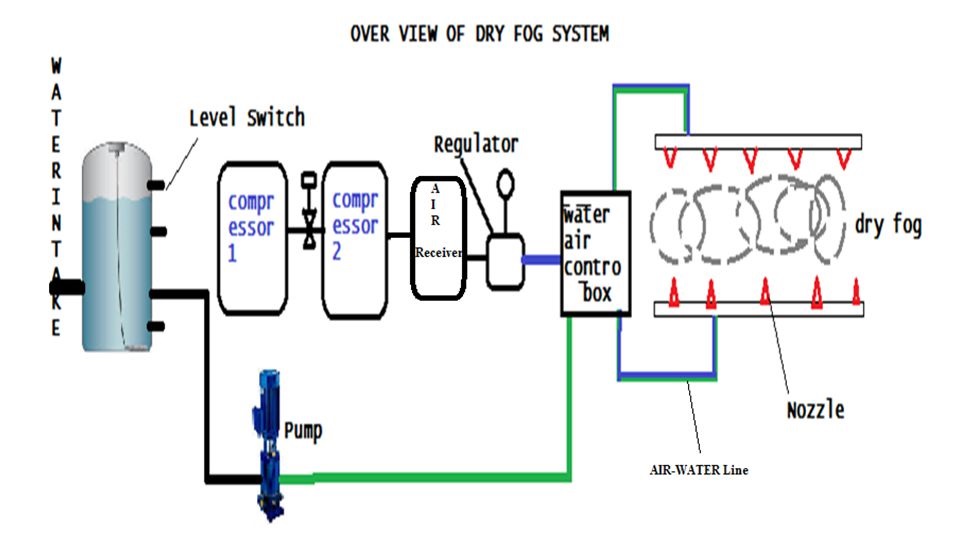

- Dry fog dust Suppression System employs high pressure of Air(3-4 bar) and low pressure of water (2-3 bar) ,which generates dry fog and being sprayed at the points of dust generated.

- Dry fog spray type Dust Suppression System is provided at all the locations mentioned above and spray angle covers 45-120 degrees.

- With Air Consumption of 5 to 6 Nm3/Hr Per nozzle.

Dry Fog dust suppression systems that are custom designed and engineered to meet the unique operating parameters of our clients.

Dry Fog systems provide the driest form of dust suppression available on the market and have been named a Best Demonstrated Technology by the US Environmental Protection Agency (EPA) for coal-handling, processing and operations of sub-bituminous and lignite coals.

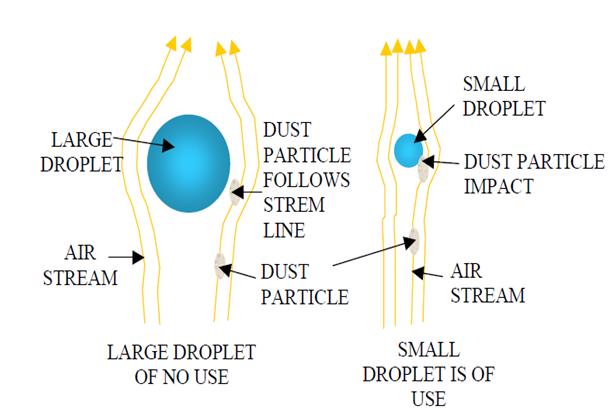

Our low flow, ultrasonic nozzles create fog droplets 1-10μm in size which easily agglomerate to dust particles as small as PM2.5 and PM10. Dry Fog adds weight to the dust particle without moisture, so that airborne particles fall back into the process with no significant wetting of the product.

Extensive scientific research has shown that for effective dust suppression to occur, successful agglomeration between the dust particles and material must take place.

When compared to alternative technologies, Dry Fog’s ultra-fine atomization can agglomerate to the widest range of particle sizes – from ultra-fine coal dust to heavier fly ash and pulverized coal.

https://www.youtube.com/watch?v=4GriK3gvUDc#action=share

Advantages

Close to 99% reduction efficiency of respirable PM10 and PM2.5 dust particles.

Less than 0.5% moisture by volume added to the product.

Returns useable material to the product stream.

Low maintenance due to ultrasonic nozzle design, which is less likely to clog than standard spray nozzles.

DSI modular design capability for future expansion of systems.

Low installation costs with no expensive plant modifications required

Trolly Mounted Fog Cannon System:

Benefits:

- Easy installation and operation.

- Low energy consumption.

- Effective and durable in use.

- Low investment costs.

- Tailored solutions.

- Different types of constructions.

Applications & Industries:

- Demolition & Construction

- Coal Handling

- Mining & Quarrying

- Steel & Slag

- Waste transfer

- Wood processing

- Odor Control

- Leachate spray evaporation

- Stockpiles

- Conveyor discharge chutes

- Mine blast dust

- Dust Hoppers & Crushers

- Loading/Unloading trucks

- General pollution/ Airborne dust

Fog Cannon System:

INTEG ENVICON PVT LTD. has been levitated by highly experienced technocrats having concern for environmental pollution in the industrial sector and has brought into the market transformed Dust suppression systems.

- The exponents have a wide experience in pre engineering, post order detailed engineering, installation and successful commissioning of all types Dust Suppression systems namely INTEG FOG CANNON.

- Equipped with nozzles with auto/manual regulation of water-mist according to the requirement as per site air-borne

Features:

- 320° DEG Auto Rotation

- 0 – 45° DEG Tilting Angle

- Eminent Fan Design & Motor

- Electrical Panel

- High Pressure Booster Pump

- Trolley Mounted

- Chemical Dosing Unit (for odor removal)

Post Mounted Fog Cannon:

The sophisticated composite cone, designed according to the latest discoveries in flow technology, ensures high energy efficiency, lowers noise emissions. All models are made of rugged, rust-free or galvanized components and come with a dual filter system to keep the nozzles from getting clogged.

Sprinkler Water Spray System:

Sprinklers are placed on Post to cover he height and radius of the yard area.It is designed to obtain higher efficiency in lower pressure also.

- Type of nozzle : Sprinkler

- Flow rate/Pressure : 20 to 600 LPM/3-6 bar max.

- MOC of Sprinkler : Cast AluminiumBody), Aluminium(Nozzle)

- Angle of Rotation : 180 to 360 degrees

Benefits:

- Convenience: The most obvious reason to go automatic is to make watering a less hands-on experience. You can set a timer so the sprinklers automatically pop up and water your at set times on certain days of the week.

- Aesthetics and safety: There’s nothing attractive about a garden hose stretching across your lawn. If you don’t put the hose away after every watering session, this sight is a requisite side effect. The hose is also a tripping hazard for children and pets playing in the yard. In contrast, automatic sprinkler heads pop up out of the ground, water your lawn and disappear again when they’re finished. This makes automatic sprinklers the safer, more aesthetically pleasing option.

- Water the optimal amount: Advanced automatic sprinkler systems feature weather and soil moisture sensors to deliver the right amount of water right when it’s needed. By sensing rain, an advanced system will skip the scheduled watering to avoid over-saturating and save you money.

https://www.youtube.com/watch?v=X9QkJGZ0g5s

Cold Fog Dust Suppression System:

- Cold Fog Dust Suppression System uses high pressure water fogging which creates a ultra-fine fog consisting of very fine water droplets (10 micron size). (Defined as Dry Fog) in diameter.

- These tiny water droplets absorb even the smallest dust particles in the air, yet fall to the ground without wetness. Particularly suited for dusty environments.

Benefits:

Low Initial Cost. Low Operating & Maintenance Cost. Operating at 1500 PSI, Cloud Tech Dust Suppression System requires no costly air compressors, making the initial outlay lower than any other type of dust suppression system. Cloud Tech Dust Suppression System can be installed for as little as 60% of the conventional bag filter type system. It can operate on as little as five percent of the total energy of a conventional system.

- Our dust suppression systems help you meet environmental standards: Custom installations can reduce dust to required levels, for environmental and worker safety standards,smallest droplets give maximum dust control.

- Inexpensive to operate: Low water and electricity consumption save running costs.

- Low Maintenance: With no moving parts in the fogger, you will have years of reliable low-maintenance operation.

- Reduces PM-10 levels in open plant areas by 50% or more – Will remove much of the finer dust particles – Safer than bag houses. No fire hazard – Can be used in high humidity conditions – Cools workers on jobs where hot-dry air is a part of work environment – Traps dust particles without over-wetting material.

Each Dust Suppression System is custom designed to catch and suppress dust in the most effective way at any given site. The atomization nozzle and delivery system create a 10-micron fog droplet without using a air compressor, resulting in exceptionally cost effective PM-10 suppression. Lightweight, compact, minimum of interference with plant and worker activity and easily installed.

Chem Jet Dust Suppression System:

- In Chem Jet Dust Suppression System,type of chemical used is DE-FORGE.

- It is mixed with water and Sprayed with Full Cone nozzle at 3-4 bar pressure to produce water droplet size of 70 to 120μ and the nozzle angle coverage will be 45-120 degrees.

- Chem-jet is used to lower the surface tension of water allowing the droplets to spread further and penetrate deeper into the material pile and equivalent efficiency is possible with less water.