Bag Filters:

- A baghouse,also known as a baghouse filter, bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air.Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses to control emission of air pollutants.

- Baghouses came into widespread use in the late 1970s after the invention of high-temperature fabrics (for use in the filter media) capable of withstanding temperatures over 350 °F (177 °C).

- Unlike electrostatic precipitators, where performance may vary significantly depending on process and electrical conditions, functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

Types of Bag Filters:

There are basically 3 types of baghouse filters

- Machanical Shakers

- Reverse Air

- Pulse Jet

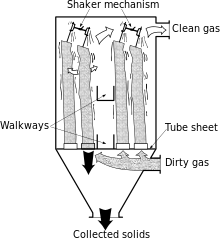

Mechanical Shakers:

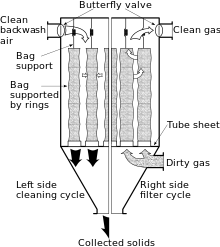

In mechanical-shaker baghouses, tubular filter bags are fastened onto a cell plate at the bottom of the baghouse and suspended from horizontal beams at the top. Dirty gas enters the bottom of the baghouse and passes through the filter, and the dust collects on the inside surface of the bags.

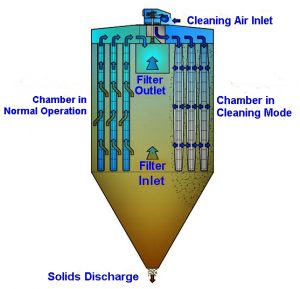

Reverse Air:

Reverse Air:In reverse-air baghouses, the bags are fastened onto a cell plate at the bottom of the baghouse and suspended from an adjustable hanger frame at the top. Dirty gas flow normally enters the baghouse and passes through the bag from the inside, and the dust collects on the inside of the bags.

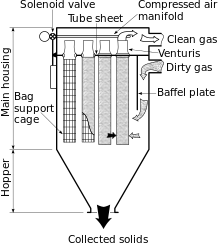

Pulse Jet:

In reverse pulse-jet baghouses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the baghouse. Dirty gas enters from the bottom of the baghouse and flows from outside to inside the bags. The metal cage prevents collapse of the bag.