Spray Nozzles:

- A spray nozzle is a simple device used to break apart a fluid flow into a spray pattern. Despite the apparent simplicity of nozzles there are a very large number of different products in our range reflecting the multitude of ways different industries need to spray various fluids.

- Our product range consists of tens of thousands of nozzle design variants and we have built our entire business around advising on and selling the humble nozzle which is why we are the spray nozzle people!

- Various nozzle designs are deployed to create these patterns and details on each can be found in the sections below.

- Air atomising nozzles have their own section as they can be used to create many different patterns and work in a fundamentally different way to hydraulic nozzles.

- Similarly the various tank cleaning nozzles and heads available from BETE are organised into their own section. Finally we have a section for special purpose nozzles that do not logically fit within any of the other sections.

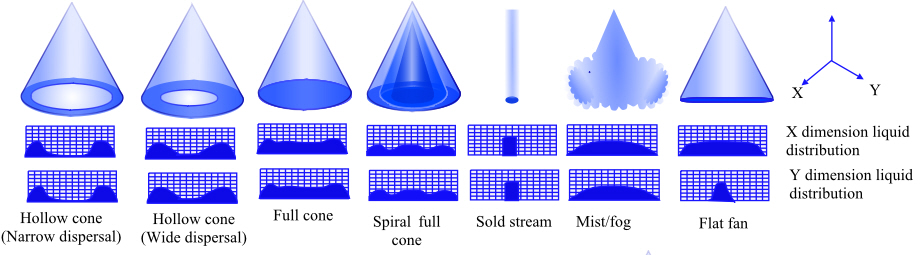

There are 5 basic spray pattern types:

- Flat Fan.

- Solid Stream.

- Full Cone.

- Hollow Cone.

- Mist/Fog.

Flat Fan Nozzle:

- The flat fan pattern is effectively a line of spray. The impact of this spray is high when compared to full or hollow cone spray patterns, but not as high as a solid stream nozzle.

- The droplet sizes produced by this type of nozzle are larger than cone nozzles, although very fine droplet flat fans can be produced by some air atomising flat fan nozzles.

- In order for a flat fan nozzle to cover an area, some kind of relative motion is required.

- Commonly this motion is provided by a conveyor moving product under a series of flat fan sprays.

- Alternatively the nozzle itself can be in motion to provide complete coverage.

Solid Stream Nozzle:

- The solid stream nozzle, also called a solid jet nozzle, is the simplest of all nozzles, being little more than a circular orifice at the end of a funnel.

- Nevertheless, there are a number of different design variants giving different spray properties.

- Solid stream nozzles give the highest impact of any spray pattern as the full momentum of the liquid is concentrated into a small area.

- Droplet size is irrelevant in solid stream nozzles as, unlike all other nozzles, the liquid is not automised.

Full Cone Nozzle:

- The most commonly used nozzle type in industry is the Full Cone nozzle.

- The nozzle emits spray in a conical shape by dispersing liquid over the cone’s interior.

- When the spray meets with a surface, a circle of spray is created with liquid present throughout.

Hollow Cone Nozzle:

- The hollow cone pattern is characterised by the heavy concentration of droplets around the edge of the spray cone.

- Little or no fluid is deposited in the middle of the cone.

- The key benefits of hollow cone nozzles are that they produce the smallest drop size which gives the spray a greater surface area allowing for a quicker heat transfer, ideal for applications such as pasteurisation where the target needs to be heated up or cooled down rapidly.

Mist/Fog Nozzle:

- A fog nozzle is a firefighting hose spray nozzle that breaks its stream into small droplets.

- By doing so, its stream achieves a greater surface area, and thus a greater rate of heat absorption, which, when compared to that of a smoothbore nozzle, speeds its transformation into the steam that smothers the fire by displacing its oxygen.